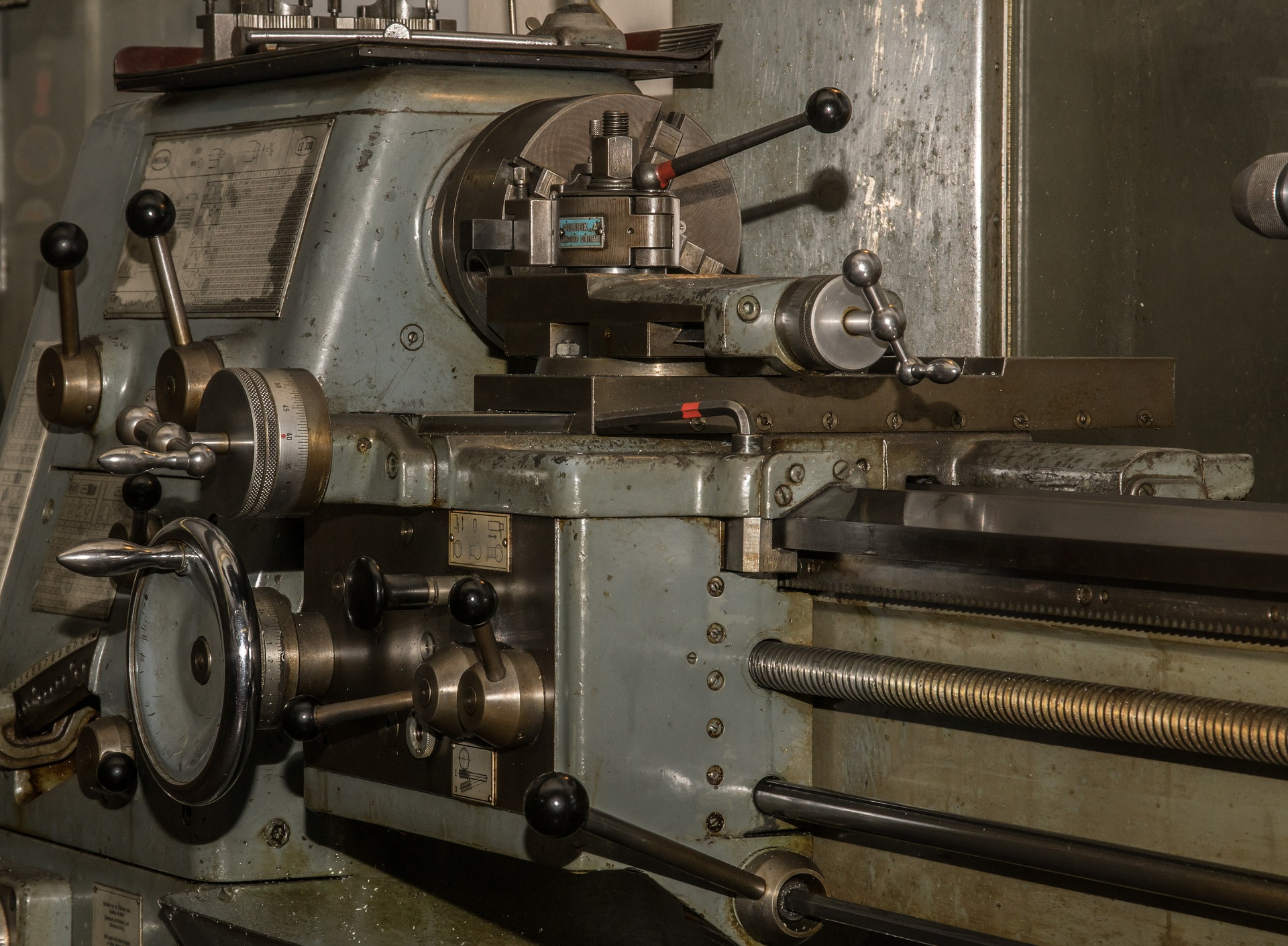

Machine Tool Repair Services

We specialize in machine tool repairs and rebuilds for all makes and models of machine tools to keep your shop running. Precision Machine can work right on site, or at our facility when more extensive work is needed.

We can help with a wide array of machine tool issues such as holding tolerance, excessive downtime, inconsistent speeds and general breakdowns. We offer preventive maintenance programs, emergency repairs, used machinery inspection and evaluations, as well as complete rebuilds.

Call us for a quote right away! (810) 367-3161

Service Calls

Just need a quick fix? We'll come to you and get your machinery up and running again. We offer on-site repairs and scraping services for any make and model of machine tools. Learn More

Complete Rebuilds

Sometimes, your machinery needs more than a simple repair. After thousands of hours of production, many parts can be worn out of close tolerances or broken altogether. You might be looking to invest in new equipment. But new machinery is expensive and your old machines are still capable of producing great work, so why scrap them? At Precision Machine Rebuilding & Scraping, we specialize in complete overhauls that save your company money and get your machines back to producing at a high level. Learn More

Scraping and Turcite

We offer scraping and turcite replacement services. If done in a timely manner, turcite replacement can be a simple process. If an issue has not been caught in time, much more work will be needed to restore precision tolerances of hardened ways. Turcite can wear out prematurely due to defective way covers and wipers, chip build-up, or failing lubrication systems. We will thoroughly inspect these critical items and replace or repair them as needed. Learn More

Machine Tool Alignment

Leveling and alignment can dramatically improve quality of parts as well as prolong the life of your machine tool. Learn More

Preventive Maintenance

Catch problems before production grinds to a halt. A good preventive maintenance program is the best way to minimize downtime and maximize the uptime of your machine shop. Learn More